Hearing protection is often underestimated as a worksite health and safety hazard. This is understandable when – unlike most other workplace hazards – the symptoms of hearing loss often take a very long time to manifest themselves, and very little can be done once the damage has been incurred.

These are some of the hearing protection measures that can be taken to minimize noise-induced hearing loss.

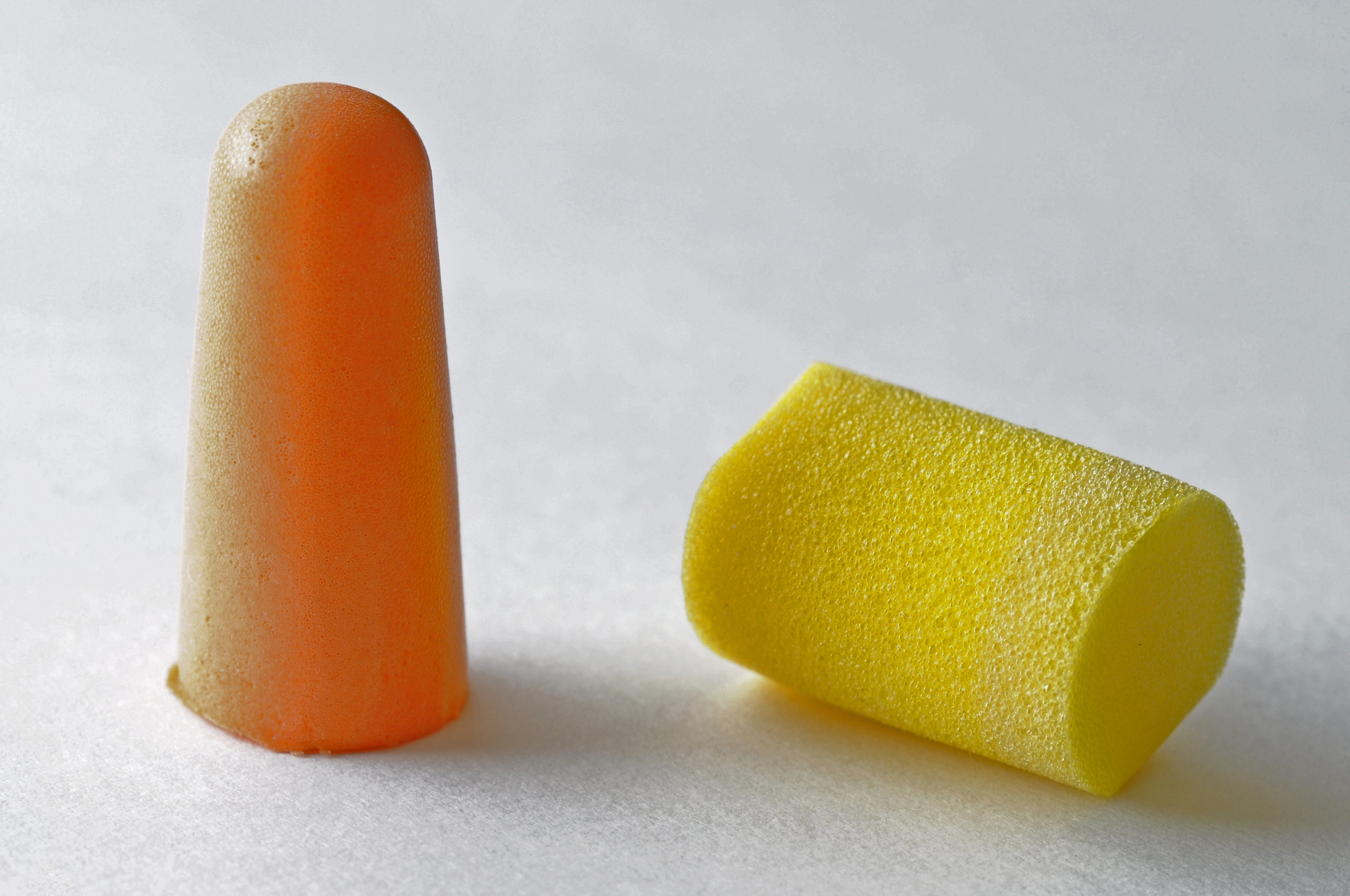

Earplugs

It is generally considered that the best form of hearing protection you can get is with a pair of (good quality) earplugs. This is because the plug seals the ear canal, absorbing noise before it reaches the ear drum. Another hazard presents itself here, however; earplugs should not be shared, lest an ear infection develops in the users’ ears.

Foam earplugs are cheap and very effective.

Ear Muffs

Also a highly effective form of hearing protection, ear muffs should sit comfortably on the head and over the ears, forming a seal between the two. Ear muffs are a little more cumbersome than ear plugs, however, and should not impede any headwear PPE (personal protective equipment). Unlike earplugs, however, ear muffs can be shared among workers.

For enhanced hearing protection, use ear muffs over a pair of ear plugs.

Ear muffs are less reliable as hearing protection, but are more convenient for intermittent use.

Acoustic Screening

This is a form of hearing protection that takes into consideration larger numbers of workers and even the general public around the worksite, ensuring that noise from the site minimally affects the community beyond. Echo Barriers are acoustic barriers that can be configured to fit around perimeters of all shapes and sizes and is capable of reducing noise by 15–30 decibels in the field while boasting the portability and visibility necessary for use on worksites.

Reduce Noise At The Source

The most effective way to prevent noise-induced hearing loss is by eliminating the noise source itself. In the construction industry this is difficult with machinery, power tools, generators and other equipment emitting; so what’s the alternative? Purchase quieter equipment to begin with. On older equipment, where possible, try to repair or individual offending parts. Often it is loose or poorly lubricated mechanisms that cause noise that atypically loud for a particular machine.

Portable Noise Control

Echo Barrier was designed to help contractors effortlessly have their noise mitigation issues taken care of, so that they can get on with their job without worrying about disturbing the community.

Distribution available worldwide.

.png?width=660&name=20141228_EarlsCourt_%20(368%20of%20375).png)