Implementing noise mitigation measures like using Echo Barrier temporary noise barriers is the first step to lowering the impact of noise from a worksite on the surrounding environment and communities. However, paramount to the effectiveness of this application is an understanding of how and why Echo Barriers are used to block noise.

Read: Measures To Reduce Noise Hazards Onsite

The Echo Barrier noise control system is an innovative noise abatement tool, making effective noise control possible on temporary worksites with its portable, weatherproof, and modular design. Echo Barriers can be hung from any structure such as standard temporary fencing, scaffolding, or hoarding (note: always be wary of structural wind loading).

The Echo Barrier system is the most effective temporary noise control tool available. Without correct implementation, however, you risk rendering it ineffective. To get the most out of Echo Barriers, follow the guidelines outlined in this article (see more information in the official Echo Barrier installation guides).

Hanging the barriers

Each Echo Barrier comes equipped with an installation kit, including proprietary hooks and straps. The initial barrier should be hung from two hooks – one in each upper corner – with each subsequent barrier sharing its first hook with the previous barrier. Zip ties or any other securing device can also be used to fix the barriers.

Each Echo Barrier shares a hook with the previous, causing them to overlap

Building a sound curtain

In larger openings where erecting a structure is difficult or simply not possible, Echo Barriers can be hung vertically off one another from a passageway or position above the opening to form a sound curtain. As part of the installation kit, Echo Barrier are supplied with sturdy Buffalo Bolts, which connect free-hanging barriers to one another. Simply ensure the top row of barriers is firmly secured, and assemble your configuration of the noise control system as necessary using the bolts.

Using the orange bolts, a free-hanging curtain can be configured using Echo Barriers.

Echo Barriers must overlap to avoid ‘leakage’

Wonder why the acoustic absorbent infill doesn’t reach all the way to the edges of the barrier? This is because without sufficient space for the barriers to overlap and be secured, the barriers won’t perform as well, rendering your noise mitigation efforts far less effective. Air gaps between the barriers allows noise to escape unattenuated, so they must be minimised (bear in mind the necessity of the eyelets which allow a negligible amount of noise to pass through in order for the barriers to be mounted securely).

Pay particular attention to corners where barriers change direction, and ensure there are no gaps that will allow sound to escape. The flexibility of the barriers allows them to even be wrapped around corners.

Face front of Echo Barrier away from noise source

It is critical that the branded face of the Echo Barrier face away from the noise source. Echo Barriers have a very high absorption rating, with the H10 absorbing 100% of noise in the tested 500Hz bandwidth, however this can only be achieved with the correct orientation of the barriers.

The rear outer layer of the Echo Barrier is made of a durable semi-absorbent mesh that allows noise to pass through while keeping water from entering. This also allows the barrier to be quickly and easily cleaned with a pressure washer after use.

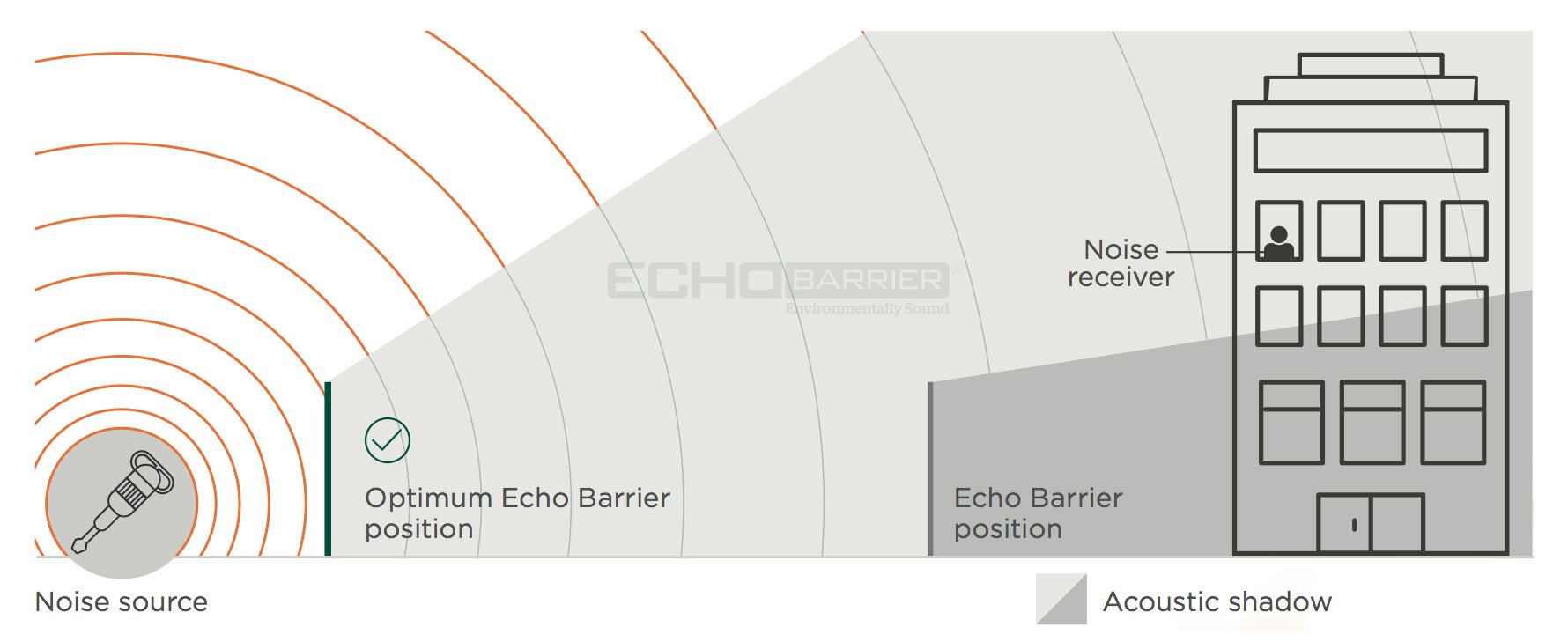

Consider the acoustic shadow

The acoustic shadow is the “safe zone” cast by the correctly mounted barriers. Where the barriers obscure sight of the noise source/s, noise is being effectively attenuated. As an example: if you intend to guard passersby from a noisy site, any machinery and sources of disruptive noise should not be visible from the footfall area.

Read: Acoustic Shadow Explained

The modularity of the Echo Barrier noise control system allows for flexible configuration, making it easy to control the size and direction of your acoustic shadow, and even the degree of attenuation; H-Series barriers can be double layered for augmented noise reduction and absorption.

Echo Barriers are lightweight and portable, allowing for optimal positioning and maximum noise reduction.

Double layering Echo Barriers

H-Series Echo Barriers are designed to be double-layered, providing further noise attenuation. It is important to take this extra structural loading into consideration if you proceed with double layering.

By applying extra mass to the configuration, even less noise escapes beyond the assembled barriers. To do this, overlap the second layer of barriers over the initial layer to ensure its efficacy. Do this by securing the edges of new barriers from the center eyelets of the original barriers.

Apply hooks or zip ties to the center eyelet on the initial layer of Echo Barriers, and begin hanging the new layer from there.

Always address safety warnings on barriers and ensure structure can handle extra loading. Refer to the installation guide for more information, which can also be found with other relevant Echo Barrier documentation by scanning the QR code found on the face of every barrier.

Cleaning Echo Barriers

Echo Barriers are designed to withstand the tough conditions of a work environment and exposure to the elements, so it is likely they will get dirty after use. To clean, simply hang the barriers (without overlapping) freely from a fence or other support and go over them with a pressure washing. Either flip and repeat or spray through the grate in the fence to clean the opposite side. Leave the barriers to dry before rolling and/or storing them.

Cleaning Echo Barriers is a quick and simple process using a pressure washer.

Repairing Echo Barriers

Like any piece of equipment, Echo Barriers are susceptible to damage. Contact with sharp or heavy objects and equipment can result in tears in the barrier membrane. To repair such tears, Echo Barrier can provide materials to seal the damaged area, either vinyl for the face or mesh for the noise-absorbent rear of the barrier.

Take a patch of the appropriate material and cut it rectangularly and slightly larger than the damaged area. Gently heat the edges of the damaged area with a heat gun, taking care to not melt the surface of the panel. Place the patch over the damaged area, ensuring the edges are covered by the patch. Using the heat gun, heat the edges of both the patch and the damaged area. Without melting, they should become sufficiently soft to be pressed together. Use a hard roller to press together the patch and the edges of the damaged area, ensuring that they won’t separate once they have cooled.

Transportation and storage of Echo Barriers

All H-Series barriers are uniform in size and configurability, making not only application but also transportation a simple procedure. Echo Barriers can be stacked on a standard pallet up to x barriers in height, which amounts to a maximum weight of

For easy handling, Echo Barriers can be rolled and clipped shut, allowing personnel to carry two 6ft+ barriers at a time.

Read: Noise Barrier Materials – Which Are Most Effective?

Why acoustic barriers? Can’t I just use other materials?

Of course; most materials are going to provide at least a little sound transmission loss, preventing an amount of noise from passing through it. However, consider this: how quickly can you build a brick wall noise barrier? At what expense for the materials, time, and labor? Let’s say the noise source isn’t stationary, and is required in multiple locations over the period of a project – will you pull down the wall and rebuild it in its new location? Furthermore: what ability does the material have to absorb noise? That’s to say, what is its absorption coefficient? If you’re not careful, you could be trapping the noise and reflecting it back toward the noise source and any people internal to the barrier.

Read: Acoustic Barriers vs. Hoarding

These pain points of temporary noise control are addressed using Echo Barriers, which make installation, mobility, and removal of high-performance noise control more cost effective and practical than any other method. The barriers’ acoustic infill’s ability to absorb noise rivals products and materials with twice the mass of an Echo Barrier.

Echo Barrier: Environmentally Sound

The initial development of Echo Barrier was inspired by the need to address noise pollution being created by worksites, where it was deemed that cost-effective temporary noise mitigation was unrealistic.

It is dangerous to undertake loud activities in populated areas, affecting the health and productivity of people, businesses, and even wildlife in the vicinity. The Echo Barrier eBook “The Rising Toll of Noise Pollution” details the true extent of harm caused by this kind of disruptive activity; download to learn more about the reason for Echo Barrier and the necessity of portable noise mitigation.