Understanding the importance of implementing practical noise mitigation strategies, such as the use of temporary noise barriers from Echo Barrier, is essential. These temporary noise barriers are the best way to reduce the impact of noise from a work site on the surrounding community and environment. Understanding how and why Echo Barriers are used is crucial to fully appreciate their effectiveness in reducing noise.

However, as with all technologies, correct and safe usage is the only way to get the best results

The portable, weatherproof, and modular design of the Echo Barrier noise control system makes it a cutting-edge tool for noise reduction that enables efficient noise management on temporary work sites. These barriers can easily hang from various structures like scaffolding, temporary fencing, or hoarding. However, caution must be taken with regards to wind loading.

Among all of the available temporary noise control tools, the Echo Barrier system has proven to be the most effective. However, to ensure optimal performance, it must be installed correctly. It is essential to follow the guidelines provided in this expert article in order to get the most out of Echo Barriers. (Refer to the official Echo Barrier installation guides for more detailed information.)

Hanging the barriers:

Each Echo Barrier comes with an installation kit that includes proprietary hooks and straps. The main barrier must be hung from two hooks, one in each upper corner. All subsequent barriers should share their first hook with the barrier before them. Additionally, zip ties or other securing tools can be used to securely attach the barriers.

Building a sound curtain:

In certain situations where building a structure is difficult or not feasible, Echo Barrier’s temporary sound barriers can be hung vertically from one another to create a sound curtain. This can be done by connecting the free-hanging barriers to one another using the Echo Barrier vertical fitting bolts, which are included in the installation kit. Using the bolts, build the noise control system in the correct configuration, making sure the top row of barriers is firmly attached.

Echo Barriers must overlap to prevent sound leakage:

Some may wonder why the acoustic absorbent infill does not extend to the edges of the barrier. This is because, in order to reach optimal performance, the barriers must have sufficient space to overlap and be secured. Noise mitigation efforts are much less effective when there are lots of air gaps between the barriers, as this allows noise to escape without attenuation. Pay close attention to the corners where the barriers change direction, as this is where there are often gaps. The barriers' flexibility enables them to be wrapped around corners when needed.

Face the front of the Echo Barrier away from the noise source:

Ensuring that the branded face of the barrier is pointed away from the noise source is crucial for maximizing Echo Barrier's noise-absorbing capabilities. Echo Barriers have a high absorption rating; for example, the H10 barrier absorbs 100% of noise in the tested 500 Hz bandwidth. However, the barriers need to be correctly positioned to achieve this. The Echo Barrier's rear outer layer is made of a tough, semi-absorbent mesh that keeps water out while letting noise through. This design feature allows for efficient and easy cleaning of the barrier with the use of a pressure washer.

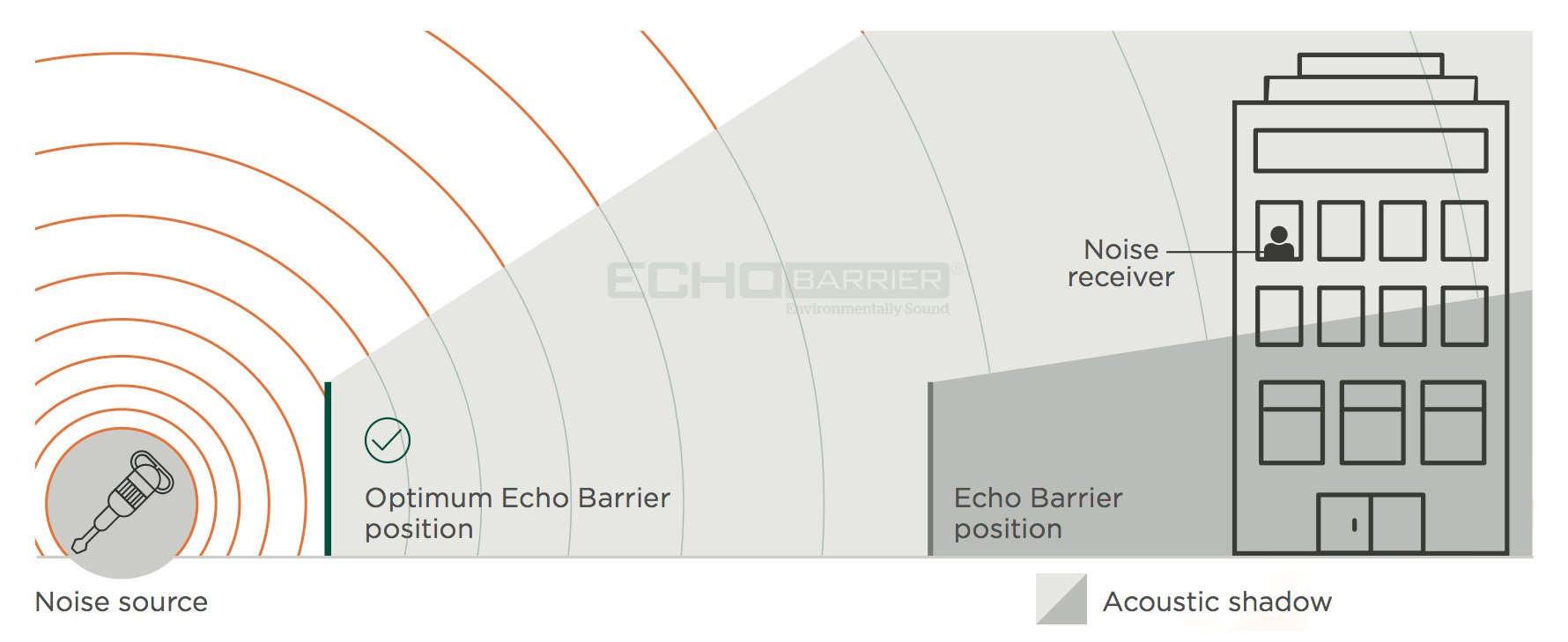

Consider the acoustic shadow:

The acoustic shadow refers to the “safe zone,” which is created when the barriers are properly mounted. Noise is successfully reduced when the barriers block the view of the noise source(s). For example, if you want to protect people from a noisy site, then all machinery and sources of noise should not be visible from the footfall area. The modularity of the Echo Barrier noise control system allows for flexible configuration, allowing control over the size, direction, and degree of attenuation of the acoustic shadow. For better absorption and noise reduction, the H-Series can be double-layered.

Double-layering Echo Barriers:

The Echo Barrier H-Series is designed to be double-layered to provide further noise attenuation. However, when using double layers, it's vital to take the additional structural loading into account. By increasing the mass of the configuration, even less noise escapes beyond the assembled barriers. This can be achieved by overlapping the second layer over the initial layer of the barrier, ensuring proper efficacy. Then, using hooks or zip ties, secure the edges of the new barriers to the center eyelets of the original barriers.

Always take note of the safety warnings on the barriers and make sure that the structure can handle the additional weight. For more detailed information, you can refer to the installation guide and other relevant Echo Barrier documentation. You can access this information by scanning the QR code found on the face of every barrier.

Cleaning Echo Barriers:

Echo barriers have been designed to withstand exposure to the elements and the harsh conditions of work environments. The barriers are bound to gather dirt and dust, so cleaning them has been made easy. You can do so by hanging the barriers on a fence or other support and then using a pressure washer to clean them. The barriers should not be overlapping. Make sure that you clean both sides of the barriers, and then allow them to dry properly before rolling them up and putting them away.

Repairing Echo Barriers:

Echo Barriers are prone to damage, much like any other piece of equipment. Tears in the barrier membrane can easily occur when it comes into contact with heavy or sharp objects. In cases like this, Echo Barrier provides materials that can seal the damaged area, including vinyl for the face or mesh for the noise-absorbent rear of the barrier. To repair any tears, cut a rectangular patch slightly bigger than the damaged area from the appropriate material. Use a heat gun to gently warm the outer edges of the damaged area, being cautious not to melt the surface. Put the patch over the damaged area and make sure that all of the edges are covered. Apply heat to the edges of the damaged area and the patch until they become soft, then press them together with the help of a hard roller and make sure that they stay fused once cooled.

Transportation and storage of Echo Barriers:

All barriers in the H-series are uniform in configuration and size, which makes them easier to use and transport. All Echo Barriers can be stacked on a standard pallet, keeping in mind that the maximum height must correspond to the maximum weight. To make handling the barriers easier, the lightweight Echo Barriers can be rolled and securely clipped shut, allowing people to carry two 6ft+ barriers at a time.

Wind loading and safety

Ensure proper consideration of wind loading when hanging barriers from any structure. Follow instructions and all safety warnings in the

user manual to ensure correct installation and thorough consideration of wind loading requirements.

Why choose acoustic barriers over other materials?

While a variety of materials can reduce sound transmission to a certain extent, it is important to consider the efficacy and practicality of each alternative. For example, building a brick wall noise barrier is not only expensive and time-consuming, but it is also unlikely that it will offer the same level of noise reduction as Echo Barriers would. On top of this, if the noise source needs to be relocated, then rebuilding the brick wall becomes impractical. It is also important to consider a specific material's ability to absorb noise, as using an inappropriate material may lead to trapping and reflecting noise back toward the noise source and individuals within the barrier, Echo Barriers offer unparalleled sound absorption especially considering their lighter weight, up to 42db at certain frequencies.

Addressing noise pollution and creating a better world:

Echo Barrier was created in response to the need to alleviate noise pollution brought on by construction sites when cost-effective temporary noise mitigation seemed impossible. The overall health and productivity of people, companies, and even wildlife are at stake when loud activities are conducted in populated areas. To get a better understanding of the detrimental effects caused by these activities, it is recommended to download the Echo Barrier eBook, "The Rising Toll of Noise Pollution." Echo Barrier puts the needs of people and the environment first, and Echo Barrier is committed to reducing noise pollution and contributing to a more environmentally sound world.